Manufacturing

All our pieces are crafted in England. We cast and polish most of our pieces in AA Fine Castings workshop in London. This talented team is helping us produce the highest quality jewellery.

Production process consists of 6 main steps.

Step 1

We come up with the concept of the piece only when we are inspired enough and sincerely believe in what we are doing and in the future piece being useful is satisfying it’s purposes.

Step 2

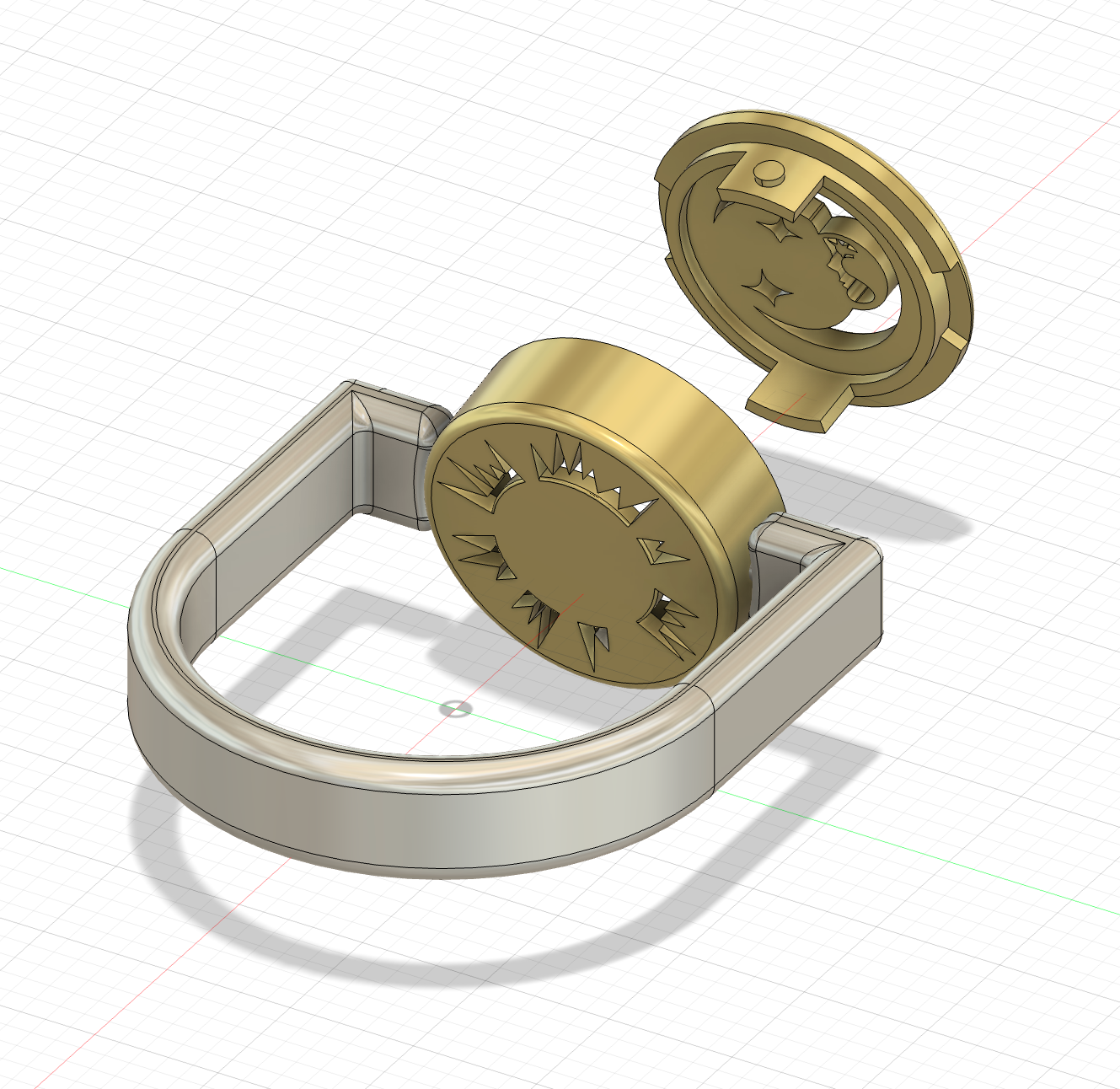

Then we design the future piece in 3d modelling software.

We usually solve various interesting engineering problems at this stage. For example to create a model for our secret flipping ring we invented a locking mechanism that will keep all your secrets safe and is made so that it could not be opened easily

Step 3

We build prototypes using scaled-up 3d-printed models to test and fix any shape imperfections.

This is the most fun part!

Step 4

We share our model, hopes and aspirations with the team in AA Fine Castings to produce a wax copy.

Step 5

The wax model is melted once and for all.

Yes we couldn’t cope without a little destruction in the process, but it's a worthwhile sacrifice.

The first baby piece made from metal is born.

Step 6

Now careful hands are to polish, massage, cherish and nurture the future piece so that it looked like this.